Dealing with commercial roof leaks is never fun, especially when they are unexpected. As a contractor that has diagnosed and repaired many commercial roofs, we have found commonalities between the majority of leak repair calls we receive.

In this post we’ll give a brief rundown of the most common leaks that we find on commercial roofing systems.

Failed Seams

TPO is made watertight through heat-welding the material to itself. When done correctly, the two pieces of TPO effectively become one and will remain watertight over the entirety of the roof system’s service life.

In the field of the roof, a robot welder is used to accomplish this. At corners and penetrations, a hand welder is used. Because of the larger margin of error inherent with hand-welding and working around all the angles created by corners and penetrations, it is not at all difficult for a poor weld to occur.

Pitch Pans/Sealant Failures

Pitch pans are flashing sleeves that are typically used around irregular roof penetrations. They are primed and then filled with pourable sealer to make the penetration watertight.

Why we see so many leaks on pitch pans is that the pourable sealer will always shrink and fail prior to failure of the field membrane or any other areas of the roof that do not rely on sealant to keep the roof watertight.

Pitch pans should be avoided and replaced with alternative TPO flashings whenever possible for this reason. When they are used, routine inspections must be conducted to ensure that the sealant is topped off when needed so water does not infiltrate.

Any other parts of a roof that only rely on sealant to keep water out, such as exposed termination bars, will often fail and cause leaks prior to the remainder of the roof system as well.

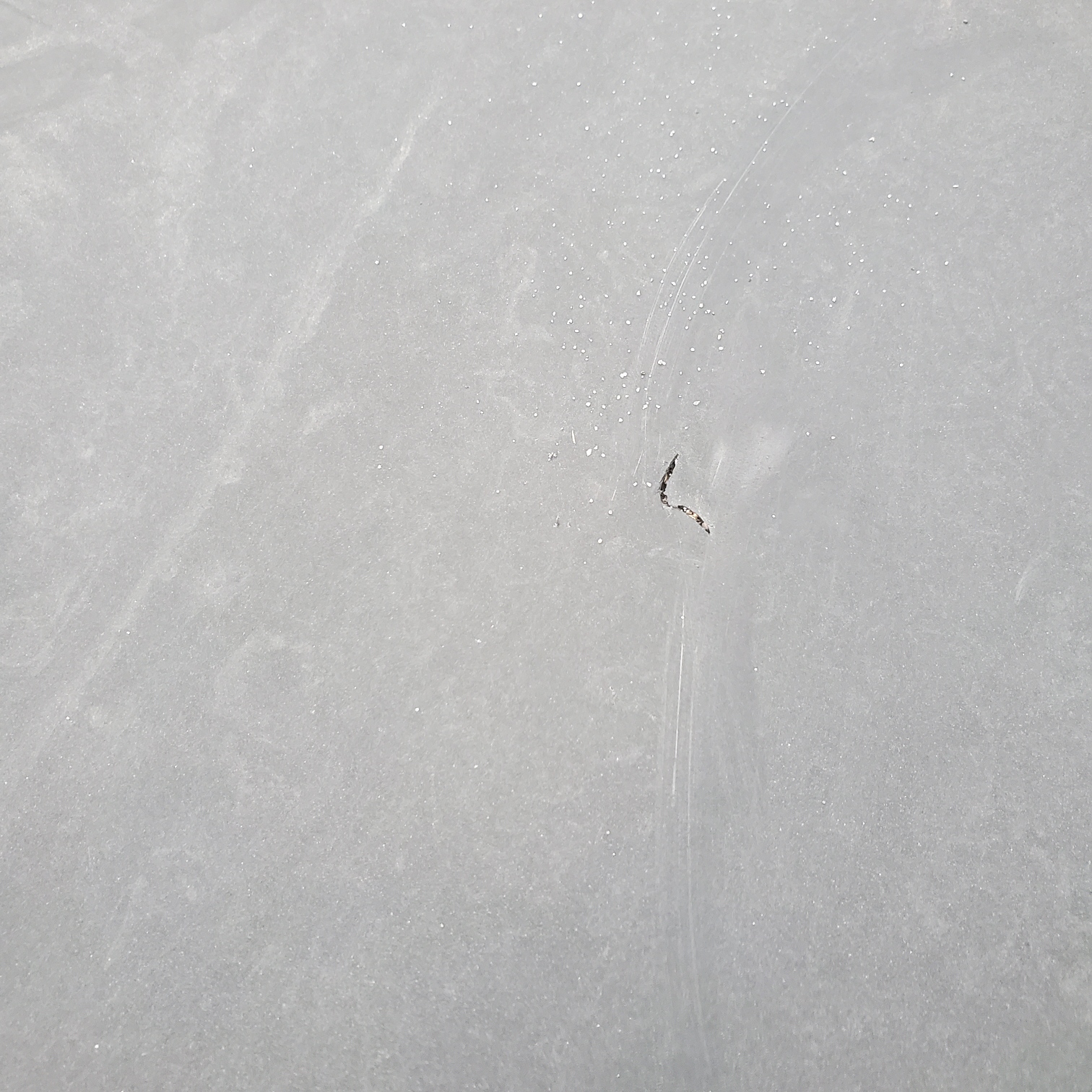

Mechanical Damage

We often trace leaks to cracks, punctures, or pinholes in the field of the membrane. While TPO is generally a very strong and durable material, it is still vulnerable to damage caused by any sharp objects.

These types of leaks can be very difficult to trace due to their small size, especially when the membrane has accumulated dust and dirt over time. Whether created during the original installation by workers dragging tools, from an HVAC contractor stepping on a loose screw, or falling debris, these holes can create large problems for your roof system.

Summary

Leaks can form in several ways on virtually any part of a commercial roof system, but hopefully this post helped to demonstrate some of the more common leaks we routinely find. For more information on possible commercial leak causes or if you have a pesky leak that you need addressed, please don’t hesitate to get in touch!